|

||

|

||

| overview General info Sales enquiry Engineering enquiry FAQ's | ||||

| General info product support | ||||

If the information or support you seek is not contained below, please do not hesitate to contact a member of the Sales Team and they will ensure that you receive any further assistance and support that is necessary. |

||||

| Hardware compatibility | ||||

All products manufactured by Cursor Controls use precision made stainless steel components for the important ball running assembly and a combination of high grade stainless steel or hardened steel bearings, specialist machined or moulded housings to produce the best Trackerball solution. Many of the Trackerball products use components tested far beyond the expectation of the product, and can endure some of the harshest operating demands experienced in industry today. |

Special patented techniques are employed in the assembly of larger Trackerballs to reduce noise and vibration in the operation of the product, increasing the performance and feel of the Trackerball in the majority of installations. |

|||

| Custom solutions |

|

|||

With over 100 different Trackerball formats available and 50 years of product experience, a solution exists for almost every application and if it doesn't we will create the right solution for you. A programme of continuous product improvement and new product development ensures that we are able to retain our position at the forefront of industrial Trackerball technology. If you have a specialist application or require a specific OEM solution, we are here to work with you to achieve your objective. As one of the largest dedicated manufacturers of Trackerballs in the world, Cursor Controls already provides a cursor control solution for almost every industrial application, but with increasing demand for higher performance cursor control, the company continues to develop world leading solutions for industry.

back to top |

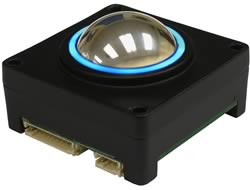

New enhancements to Trackerballs are being constantly developed... •Backlit balls Provide a welcome solution for low light environments - studio, theatre, medical and marine applications are amongst the growing list of industries where a back-lit Trackerball can produce a greater level of user interface. •Improved Floating Seal Systems Now provide a higher level of seal performance without increased roll resistance. As more applications demand dust and water sealing for harsh factory or medical installations, an increased number of sealing options, up to IP65 (NEMA 4) are now available to achieve even greater performance without compromise to the feel and response of the Trackerball. •USB (Universal Serial Bus) USB is now integrated into all Universal protocol interfaces, providing the ability for all our Trackerball range to connect to a USB bus and provide a Plug and Play hot connection to systems operating on Windows 98® or Apple®. |

|||

| Technical quicktips |

|

|||

Mechanical couples acting in mutually perpendicular axes. Common user protocols are then provisioned via electronic interface circuitry. Precision, robustness and reliability, essential to the professional user, are engineered into our product by careful selection of quality materials. All shafts are of stainless steel, running bearings are of the highest specification and plastics are proven for their structural integrity, dimensional stability, low burnability and resistance to chemical attack. |

Cursor Controls recognise the breadth of customers requirements and aim to provide an effective solution to all requests. Chassis/structural materials range from general purpose ABS through to more specialist reinforced plastics and anodized aluminum on rugged models. |

|||

| Engineering |

|

|||

All products manufactured by Cursor Controls use precision made stainless steel components for the important ball running assembly and a combination of high grade stainless steel or hardened steel bearings, specialist machined or moulded housings to produce the best Trackerball solution. Many of the Trackerball products use components tested far beyond the expectation of the product, and can endure some of the harshest operating demands experienced in industry today. |

Special patented techniques are employed in the assembly of larger Trackerballs to reduce noise and vibration in the operation of the product, increasing the performance and feel of the Trackerball in the majority of installations. |

|||

| Sealing technology |

|

|||

Cursor Controls sealing solutions range from scraper-seals to self-centering low friction IP68 PTFE sealing systems. These correspond to Index of Protection Standards... •IP51 (NEMA 2) Protected against dust (no harmful deposit) and vertically falling drops of water (condensation). •IP54 (NEMA 4) Protected against dust (no harmful deposit) and projections of water from all directions. •IP65 (NEMA 4) Completely protected against dust and jets of water from all directions. •IP68 (NEMA 6) Protection against indefinite immersion in water under a specified pressure.

back to top |

New enhancements to Trackerballs are being constantly developed... •Backlit balls Provide a welcome solution for low light environments - studio, theatre, medical and marine applications are amongst the growing list of industries where a back-lit Trackerball can produce a greater level of user interface. •Improved Floating Seal Systems Now provide a higher level of seal performance without increased roll resistance. As more applications demand dust and water sealing for harsh factory or medical installations, an increased number of sealing options, up to IP65 (NEMA 4) are now available to achieve even greater performance without compromise to the feel and response of the Trackerball. •USB (Universal Serial Bus) USB is now integrated into all Universal protocol interfaces, providing the ability for all our Trackerball range to connect to a USB bus and provide a Plug and Play hot connection to systems operating on Windows 98® or Apple®. |

|||

| Standard lead connection formats | ||||

|

||||

| Glossary of terms |

|

|||

•Floating shaft technology Introduces a degree of suspension into the shaft-bearing couples, so giving a softer feel to the Trackerball operation, reducing noise and vibration. •Mounting Back of Panel mounting: The Trackerball is mounted and fastened from the rear of a panel. Front of Panel mounting: The Trackerball snaps into a pre-formed cutout from the front of the panel leaving no fasteners visible. •Plug & Play compatibility Protocol Trackerballs emulate popular pointing device formats ensuring true plug & play compatibility. •Protocol A set of rules and formats necessary for the effective exchange of data between intelligent devices. |

•Resolution The resolution of a Trackerball indicates the number of pulses output from the device per revolution of the ball and is proportional to ball size. Larger ball devices provide greater resolutions and so enhance screen pointing accuracy. •Tracking force Where quoted, this provides a guide to the minimum tangental force applied to a Trackerball to overcome inertia. •Quadrature Term given to an output of two square waves out of phase by 90°. Latest generation Trackerballs typically have a phase error of less than 30° between channels. •Universal Serial Bus (USB) Industrial standard serial interface between a computer and peripherals. With this technology up to 127 devices can be connected to one controller without system interruption. |

|||

| NEMA standards | ||||

|

||||

| Product selector | ||||

|

||||

| back to top | ||||